PCB Assembly

PCB Assembly Steps

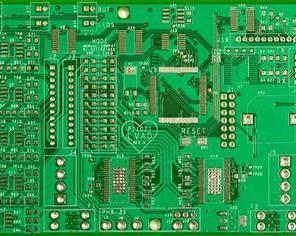

1. PCB Fabrication (Bare Board)

- PCB is manufactured from Gerber files

- Copper layers, solder mask, and silkscreen are applied

- Electrical testing of the bare board is done

Output: Empty PCB with pads, vias, and traces

2. Solder Paste Application

- Stainless steel stencil aligned with PCB

- Solder paste spread onto component pads

- Ensures correct solder volume

Used mainly for: SMT assembly

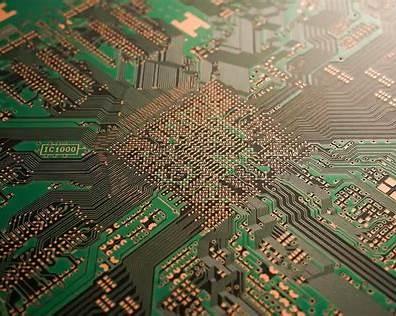

3. Component Placement (SMT)

- Pick-and-place machine mounts SMD components

- Components placed on solder paste

- High-speed and high-precision process

Components: Resistors, capacitors, ICs, BGAs, QFNs

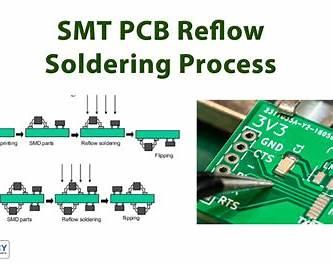

4. Reflow Soldering

- PCB passes through temperature-controlled oven

- Solder paste melts and forms joints

- Components are permanently attached

Key control: Temperature profile

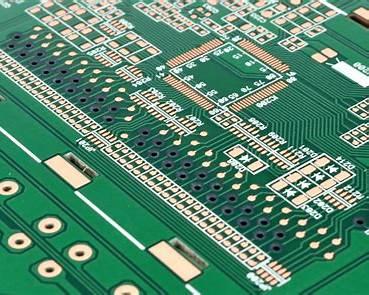

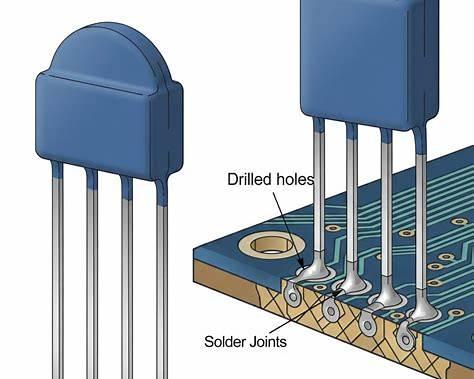

5. Through-Hole Component Insertion (THT)

- Leads inserted into drilled holes

- Can be manual or automated

- Used for connectors, transformers, large capacitors

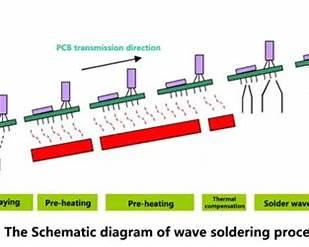

6. Wave / Hand Soldering (THT)

- Wave soldering for mass production

- Hand soldering for prototypes or repairs

- Solder bonds leads to pads

7. Inspection & Quality Control

- AOI (Automated Optical Inspection)

- X-ray inspection for BGAs

- Visual inspection for solder defects

Checks for: Shorts, opens, misalignment

8. Electrical Testing

- In-Circuit Test (ICT)

- Functional Testing (FCT)

- Confirms circuit operates correctly

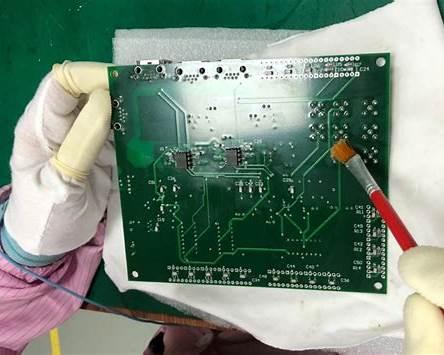

9. Cleaning & Final Assembly

- Flux residue removal

- Final visual inspection

- Preparation for coating or packaging

10. Conformal Coating

A thin, protective polymer layer applied to printed circuit boards (PCBs) that “conforms” to components and traces, shielding them from moisture, dust, chemicals, and corrosion.

Why It’s Used

- Moisture & humidity protection

- Corrosion resistance (salts, pollutants)

- Prevents leakage & short circuits

- Improves reliability in harsh environments

- Extends product lifespan

Common Coating Types

| Type | Best For | Pros | Cons |

|---|---|---|---|

| Acrylic (AR) | General electronics | Easy rework, fast dry | Moderate chemical resistance |

| Silicone (SR) | High temp, vibration | Flexible, wide temp range | Harder to remove |

| Urethane (UR) | Chemical exposure | Excellent chemical resistance | Difficult rework |

| Parylene (XY) | High-reliability | Ultra-thin, uniform | Expensive, special process |

Conformal Coating Machine (Automated / Selective)

Typical use: Medium–high volume production

Key features:

- Programmable XYZ motion

- Precise needle/spray valves

- Minimal masking required

- Consistent thickness & repeatability

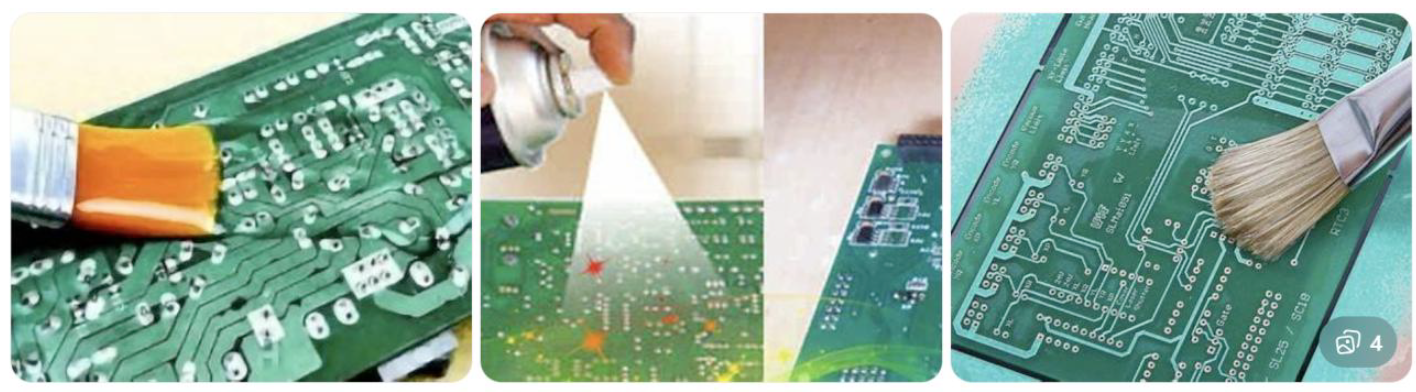

Conformal Coating Hand Application (Manual)

Typical use: Prototypes, rework, low volume

Key features:

- Brush, aerosol spray, or syringe

- Low equipment cost

- Operator-dependent quality

Box Build PCB Assembly

What PCB Box Build Consists Of

- PCB mounted inside enclosure (metal or plastic)

- Wiring & cable harnesses (connectors, terminals)

- Mechanical assembly (standoffs, brackets, screws)

- Power supplies, switches, fans, displays (as required)

- Labels & grounding points